Stanford engineers create a tiny LED display that stretches like a rubber band

The light in the display may be short-lived, but the idea behind the proof-of-concept screen may be here to stay.

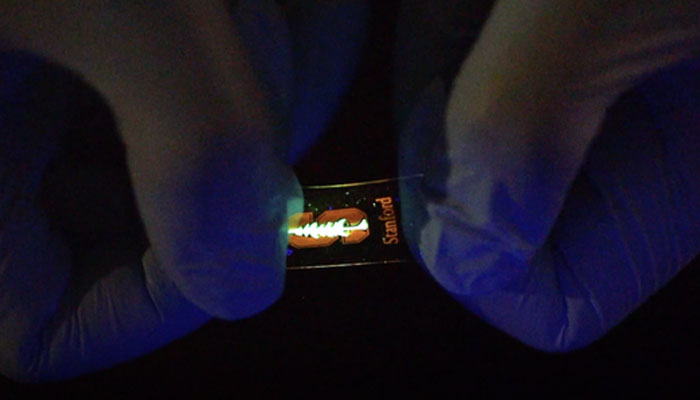

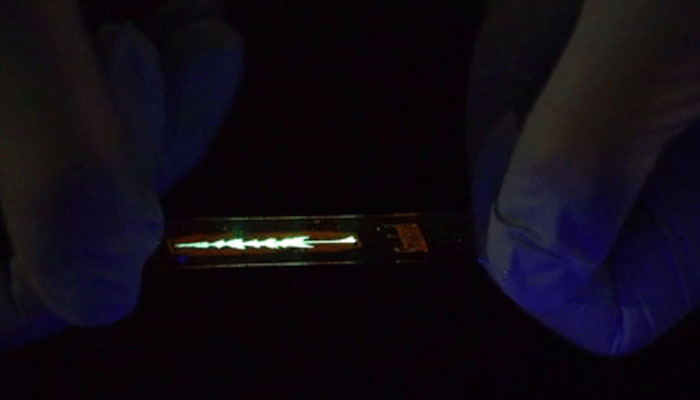

Stanford engineers turned the plastic film into mini LED displays. Bao Group Research Laboratory/Stanford University

The screen on a smartphone or TV is a rigid object and definitely not meant to stretch. But Stanford engineers may have found the first steps toward making stretchy LED screens, and their new research is exploring how to create interactive displays that could easily be part of The Incredibles’ Elastigirl super suit versus traditional LED displays Unlike conventional LED displays, which consist of liquid crystals encapsulated in a rigid casing, the LED screens, described in detail in the journal Nature on Wednesday, are made entirely of a rubber-band-like polymer material.

How traditional LED screens work

LED stands for Light Emitting Diode, and LED electronics work in a similar fashion. A typical LED screen on a TV or smartphone has several layers sandwiched in a display matrix, which must contain a liquid crystal layer between two electrode layers, some light polarizing layers, and an RGB color mask that sits between the crystal layer and the viewer.

The layers are constructed in a way that allows for a complex series of reactions to take place that culminates in a bright image. Of the two electrode layers in a display, one generates positive charges or holes and one generates electrons or negative charges.

These charges begin to move across the different layers in the presence of an electric field, explains Zhenan Bao, a professor of chemical engineering at Stanford University and an author of the paper in the journal Nature.

“When positive charges (also called holes) and electrons find each other, they combine into some kind of excited state molecule,” she said. “Then, when the excited molecule falls to a more stable ground state, light will be emitted in the form of photons.

The rationale for this setup is that voltage-controlled liquid crystals can manipulate the path, direction, and intensity of light at the pixel level (think pixels, like the tiny building blocks of a screen). Each pixel contains three sub-pixels on which color filters, usually red, green and blue, can be output in different combinations to give blocks of pixels different colors. Downscaling, the quality of colored pixels can form a picture.

Most screens currently used on computers and televisions are made of liquid crystals. “They don’t emit light. There’s a backlight [containing an LED strip], and the front of the backlight is liquid crystal. A lot of the light is basically blocked,” Bao said. “Only a portion of the light can pass through. So it consumes more energy, and the switching speed (which determines how fast the picture on the screen can change) is relatively slow.

Another disadvantage of these screens is that they are rigid and brittle, Bao noted, mainly because the substrate is made of glass, and if you try to bend or stretch it, the material that goes into the LEDs will also crack.

Things to Know About the New Stretch Concept

“What we’re doing here is trying to make a new type of display where you can bend, fold, change shape and still display an image,” Bao said. Having a screen that can change shape will allow it to fit the contours of soft or uneven surfaces. In their experiments, they stress-tested it by stretching it and poking it with a pen, and it held up just fine.

Bao and her team were tasked with making all the components of this screen resilient. “We developed a stretchable conducting polymer that can be used in two electrodes. However, since one electrode needs to allow holes and the other electrode needs to allow electrons, we also need to facilitate transport through the layers,” Bao said. . “The luminescent material here needs to be stretchable, but it also needs to emit a lot of light. We want a bright display.

She and her colleagues found a way to combine different hard and soft plastic materials to make light-emitting polymers form nanofibrous structures, which help electrons and holes find each other. “If they can’t find each other, we’re not going to put out the light,” she said. “This nanostructure forms a continuous pathway.

And, we found that by forming these nanofibrous structures, it eliminates some of the defects that used to exist in light-emitting polymers. We saw that, compared to the non-stretchable version, More light can be emitted from stretchable materials.

Not only were they able to form this nanostructure with green, red and blue light-emitting polymers, the basic colors needed to make full-color displays. After that, it was mostly an engineering problem of figuring out a way to stably stack the layers of the screen together to make a display. It consists of two outer substrate layers, two electrode layers, then a charge transport layer, and a central light-emitting layer.

For this prototype, the team showed that their screen can hold still images. To make a screen that can change the image, they need to incorporate some kind of motor that can power it. “The type of screen we have is very low resolution.

This paper is mostly about the discovery of materials and how we make pixels for displays,” Ball said. “But the pixels are still huge. The next step is we need to make them higher resolution, and we also need to make them last longer.

In its current state, this first-generation elastic screen can glow for days in a high nitrogen environment. Once exposed to normal air, the light lasts only a few hours.

“We still don’t have a good material to keep oxygen and moisture out of the light-emitting polymer, [which] would extinguish the light and make the display dim over time,” Bao said. “With the OLED displays we use today, the internals also only operate under nitrogen. But they found a good encapsulation material that blocks oxygen and moisture. That’s an important part of how the displays are actually useful.