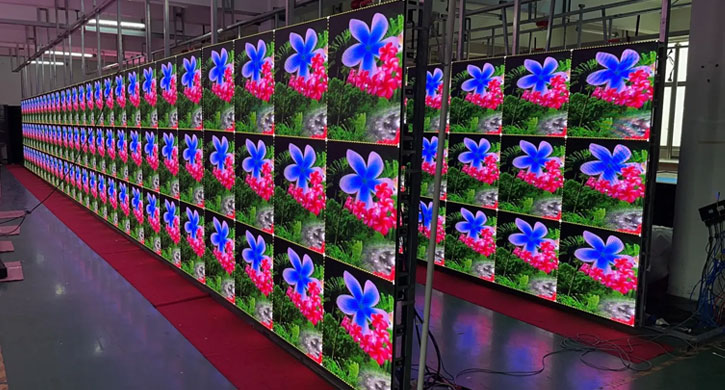

With the rapid development of the information industry, LED display has the advantages of high luminous efficiency, long service life, flexible configuration, bright colors, and strong adaptability to indoor and outdoor environments. It has become a bright spot in the modern information society. Sign.

In recent years, LED displays have been widely used in industrial and mining enterprises, schools, shopping malls, shops, public places, etc. for graphic display, advertising, information release, etc., and become the mainstream product of flat panel display. So, have you ever thought about how to realize the dynamic display technology of LED display? Let us find out!

LED display dynamic display system design scheme:

In this design system, the upper computer uses a standard computer, the lower computer is composed of AT89C51 single-chip microcomputer and its peripheral auxiliary circuits, during which the operation control commands issued by the upper computer are exchanged through RS-232C serial communication, and the lower computer is returned. The working status of the machine. In order to realize the dynamic display of the serial port control LED display, because the RS-232 signal level is different from the TTL level of the serial port of the single-chip computer, the communication interface circuit between the PC and the single-chip computer must undergo level conversion. Chip MAX232 can just complete this function. At the same time, the single-chip microcomputer should detect the received control signal, and then drive the rows and columns of the dot matrix through the driving circuit, and then control the dot matrix display screen to make corresponding display.

Display system scheme frame diagram and achievable functions:

The control command is sent by the operator through the control program or software on the computer, and is transmitted to the single-chip AT89C51 through the R232 interface. The AT 89C51 calls out the Chinese characters or characters to be displayed from the font library, and then the corresponding characters or Chinese characters are displayed on the drive circuit. LED display board.

The design of the single-chip control circuit:

The basic circuit of AT89C51 single-chip microcomputer supplies the +5V operating voltage of the single-chip microcomputer, and the 12MHz quartz oscillator is connected as the clock circuit, and the RESET button provides the system reset circuit. At the same time, because the PC serial port is in the form of RS232, which is different from the electrical standard of TTL level, the signal of the PC must pass through the MAX232 potential conversion chip.

The chip receiver converts the TIA/EIA-232-F level into TTL/ CMOS level, the transmitter converts TTL/CMOS level to TIA/EIA-232-F level. For general two-way communication, you only need to use serial input RXD, serial output TXD and ground wire GND to connect with the 89C51 serial port to ensure that the output signal is correct.

Row dynamic drive circuit module:

The horizontal dynamic drive circuit generates data signals from the input and output ports of the single-chip microcomputer. The sink current (about 1.6mA) and the source current (-10mA) of the 51 single-chip microcomputer are very small and cannot directly drive the diode, so the dot matrix diode must be driven through the driver. Since the system is a 16*16 dot matrix display, it can just use a total of 16 input and output ports of P0 and P2 to generate data signals, and then drive 16 lines of 16*16 dot matrix display through 16 driver transistors in parallel. .

Circuit parameter calculation options:

There are 16 LEDs on a row line, because the dynamic scanning method is adopted for display, and each LED is calculated with 7.5mA current, then the instantaneous current flowing through the circuit is 16×7.5mA=120mA, and the 9012 drive tube can meet the requirements. Since VCC is connected to +5V, and the voltage drop between the collector and the emitter of the transistor is about 0.3V when the transistor is in the switching state, and the voltage drop of the light-emitting diode is 0.7V, the resistance of the collector resistance is selected (5V-0.3 V-0.7V)/0.12A=33Ω. Because 51 single-chip microcomputer sinks current about 1.6mA, and at the same time, in order to make the triode work in the on-off state, the I/O port output in this circuit must be connected with a 4.7K current-limiting resistor.

Row dynamic drive circuit module:

The horizontal dynamic drive circuit generates data signals from the input and output ports of the single-chip microcomputer. The sink current (about 1.6mA) and the source current (-10mA) of the 51 single-chip microcomputer are very small and cannot directly drive the diode, so the dot matrix diode must be driven through the driver. Since the system is a 16*16 dot matrix display, it can just use a total of 16 input and output ports of P0 and P2 to generate data signals, and then drive 16 lines of 16*16 dot matrix display through 16 driver transistors in parallel. .

Software system design:

The dynamic display processing system originally designed is written in AT89C51 single-chip assembly language. Using 12M crystal oscillator, the serial port is defined as an 8-bit asynchronous serial communication port, and the baud rate is determined by the timer T1, which is 9600. The main program part mainly sets the initial value of the T1 timer, as well as the setting of the serial port interrupt control word and the initialization of each memory.

The functions implemented by the subroutine part are: receiving data sent from the computer serial port; the single-chip microcomputer scans the received button flag bit; the single-chip microcomputer turns to the corresponding branch according to the corresponding button condition to process each functional module respectively as the serial port interrupt, stop state, Mobile display module, verbatim display module.

Dynamic display control system software design ideas:

The dynamic display software control system platform adopts Visual Basic programming, and the computer needs to communicate with the single-chip computer. The functions realized by VB are mainly: firstly, the display mode flag bit must be sent through the button to notify the single-chip computer to be ready to receive control data; secondly, wait until After pressing the start button, the data to control the dot matrix display screen is sent to the single-chip microcomputer.